Fracturing a Better Future

Well Performance

According to the U.S. Energy Information Administration, natural gas consumption in the U.S. is expected to grow from 26.9 quadrillion Btu in 2013 to 30.5 quadrillion Btu in 2040, along with a growth in electricity consumption produced from natural gas ranging from 8.4 to 9.7 quadrillion Btu. Non-hydraulic fracturing provides more efficient methods to produce the required energy to meet these demands [19].

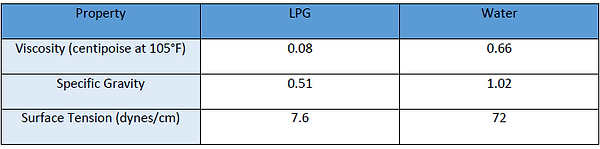

Fluids rely on viscosity, specific gravity and surface tension in order to move or flow in-between the rock space. The lower the value of each individual property, the greater the flow. Fracturing fluids serve as a way to penetrate the rocks, causing fractures that allow the transport of proppant into the reservoir rock [20].

One of consequences of using water as a fluid is a phenomenon called phase trapping. Water has higher density compared to these gases, and what occurs is water builds up around the wellhead and obstructs the flow of hydrocarbons into the well. Water also has the ability to create clay swelling and can damage surrounding salts which can cause damage to the formations around the wellhead. These will lead to a significant block for the passage of the hydrocarbons up to the surface. “The use of water-based fracturing fluids in low-permeability reservoirs may result in loss of effective fracture half-length caused by phase trapping associated with the retention of the introduced water-based fluid into the formation. This problem is increased by the water-wet nature of most tight gas reservoirs (where no initial liquid hydrocarbon saturation is or ever has been present) because of the strong spreading coefficient of water in such a situation” [8]. This results in the trapping of water in pore space and thus restricts the flow of hydrocarbons. In the long run, this means that poor well performance requires a significant amount of time to recover hydrocarbons compared to wells that have relatively high well performance values. This results in unnecessary money being spent on staff, leasing rights, equipment rental, etc.

One of the most common gases used non-hydraulic fracturing processes is LPG, which is most commonly composed primarily of propane. Due to propane’s low viscosity and surface tension, LPG can permeate through tighter pore spaces than water. Furthermore, studies have shown that the fracture lengths in rocks fractured with LPG are longer than rocks fractured with water mixtures. Propane’s low specific gravity is ideal for a fracturing fluid. Due to its low density, if a buildup of propane blocks the flow of hydrocarbons into the well, the pressure can be easily lowered to allow the propane to vaporize and thus clear itself from the well. “Mixing liquefied petroleum gases with natural gas further reduces the required drawdown and assists in a complete load fluid recovery. Consistent and demonstrated full recovery of liquefied petroleum gas and superior effective fracture lengths attest to the importance of complete fluid recovery from reserves with low flow capacity” [8, 21]. Below is a table showing the properties of viscosity, specific gravity, and surface tension for LPG vs Water:

LPG vs Water [21]

Fracture Length and Phase Trapping [22]

With the use of LPG and other gases, because of their lower properties in viscosity, specific gravity and surface tension, this phenomenon is less likely to occur. If phase trapping does occur with these gases, pressure can temporarily be dropped to allow the gas to escape [22]. An example of fracture lengths and phase trapping is shown in the following figure.

Another reason to use LPG for fracturing is that it is shown that less pressure is needed than the use of water because of its low viscosity and surface tension. High pressurized fracturing comes with a cost of potential damage to drilling equipment. Furthermore, LPG does not cause clay swelling, nor does it break up salt particles, and is therefore a better fracturing fluid than water [21].

CO2 is also a common gas that is favorable due to its high volatile properties. When the pressure is reduced, CO2 evolves from a liquid to a gas making it float to the surface. Similar to LPG as described above, this is a way to prevent blocking the flow of hydrocarbons. Furthermore, due to the viscosity of propane and butane being greater than CO2, the two hydrocarbons can carry the proppant deep into the reservoir rock. This allows for a deeper fracturing length, and once pressure is reduced and the propane and butane are recovered, a second fracture can be made with CO2. Adding nitrogen has also been shown to increase recoverability in coal and shale formations [7].

Also, as stated above, using gases that are miscible with hydrocarbons such as CO2 will prevent blockage of the oil and natural gas flow and thus reducing the potential of formation damage. Furthermore, due to the replicability of the CO2 and proppant mixture, it is relatively easy to develop effective fluids and not have to spend significant time and money on producing the best water mixture that requires many more components. Additionally, if viscosity is ever a problem, the viscosity of the CO2 fluid is easily manipulated compared to changing the viscosity of water [22].

In summary, issues with water fracturing include: water blocking in the wellhead, formation and well damage, proppant settling, and clay swelling. Furthermore, as water is often the wetting fluid, it can be detrimental to gas productivity as water can become trapped in the reservoir rock due to capillary pressure. These issues can be avoided by using gases that have lower viscosity, specific gravity, and surface tension in comparison to water. Due to these properties, fracturing with gases such as LPG and CO2 allows for a greater fracture length, which leads to an overall increase in well performance [22].